Clear HI-UV Exterior Gelcoat

-

Boat Bottom Paint

- Top Performing Bottom Paint

- Self-Polishing-Ablative Bottom Paint

- Hard Bottom Paint

- Hybrid Bottom Paint

- Water Based Bottom Paint

- Aluminum Safe Bottom Paint

- Bottom Paint Primers

- Specialty Marine Coatings

- Outdrive Paint

- Sea Hawk Paints

- Blue Water Bottom Paints

- Interlux Bottom Paint

- Pettit Bottom Paint

- Bottom Paint Remover

- Aquagard Bottom Paints

- Cleaners-Reducers-Solvents

- Boat Paint

- Boat Zincs

- New Items and Specials

- Boat Bottom Paint3

- Fiberglass and Gel Coat Repair

-

Topside Boat Paint

- Above or Below the Waterline

- Aluminum Boat Paint

-

Awlgrip Marine Paint

- Awlgrip Polyester Urethane Topcoat

- Awlcraft 2000 Acrylic Urethane Topcoat

- Awlgrip Awlcraft® SE Topcoat

- Awlgrip HDT

- Awlcraft 3000

- Awlgrip Converters

- Awlgrip Reducers and Activators

- Awlgrip Primers/Sealers

- Awlgrip Fairing/Surfacing

- Awlgrip Awl-Prep Wipe Down Solvents

- Awlgrip Corrosion Inhibiting Surface Treatments

- Awlgrip Brightwork, Varnish, Interior Wood

- Awlgrip Auxiliary Products

- Awlgrip Maintenance Products

- Camouflage Boat Paint

- Blue Water Topside Paints

- Duralux Marine Paints

- Marine Enamels

- Interlux Topside Paint

- Pettit Easypoxy

- Adhesives and Sealants

- Teak Oil and Wood Restoration

- Boat Paint Supplies

- Resins

- Cleaners and Polish

- Manufacturers

- Propeller and Running Gear Coatings

Your shopping cart is empty!

Product Description

Clear HI-UV Exterior Gelcoat is suited for a broad range of high quality, open-mold & lay-up applications. Tooling Gelcoat is marine grade formulated specifically for mold making. It has excellent leveling, flexural strength, crack resistance & UV light stability.

You will then need to add a surface treatment to the gelcoat so that it will harden, such as PVA Surfacing Agent or other air inhibitors.

Key Features:

- Weatherability

- Water/Osmosis resistance

- Durability

- Chemical resistance

- UV light stability

- Easy to apply

- Shelf Life: 90 Days when stored under cool, dry conditions.

Tooling gelcoats utilize selected resins that exhibit high heat distortion, high gloss and a hard durable surface to withstand the repeated mold cycles. Tooling gelcoat will not harden and allow for the fiberglass and tooling gelcoat to bond while being in a mold.

- Quart includes 1 Oz MEKp Catalyst

- Gallon includes with 2 Oz MEKp Catalyst

*This Item Ships From Florida Click to see Estimated Transit Times

Directions for use:

Step 1: The application site should be wiped clean of contaminants such as dust and debris. If coating a mold, the mold must be waxed, buffed, and prepped prior to catalyzing the Gelcoat.

Step 2: Gelcoat must be stirred/agitated, preferably with use of a mechanical agitator. Be careful not to whip air into the Gelcoat.

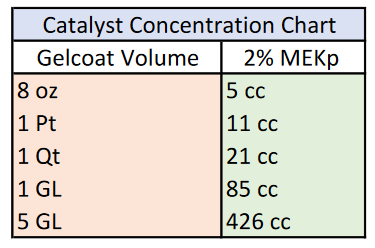

Step 3: We recommend a catalyst loading of 1.5 to 2% MEKP with a working surface and Gelcoat temperature of about 77°F. Please refer to Catalyst Concentration Chart for quantities. Mix thoroughly.

Step 4: For best results, Gelcoat should be sprayed on to the application surface or mold at about 25 mils (measured using depth gauge) in order to achieve a final optimum cured Gelcoat thickness of 18 to 22 mils.

Step 5: For out of mold applications, a second coat can be applied prior to complete cure of the initial coat, unless Gelcoat contains wax.

Step 6: The coating should be cured before sanding and buffing. Allowing to cure overnight is preferred.