Crystal Clear Epoxy Table Top Resin, 1 Gallon Kit

-

Boat Bottom Paint

- Top Performing Bottom Paint

- Self-Polishing-Ablative Bottom Paint

- Hard Bottom Paint

- Hybrid Bottom Paint

- Water Based Bottom Paint

- Aluminum Safe Bottom Paint

- Bottom Paint Primers

- Specialty Marine Coatings

- Outdrive Paint

- Sea Hawk Paints

- Blue Water Bottom Paints

- Interlux Bottom Paint

- Pettit Bottom Paint

- Bottom Paint Remover

- Aquagard Bottom Paints

- Cleaners-Reducers-Solvents

- Boat Paint

- Boat Zincs

- New Items and Specials

- Boat Bottom Paint3

- Fiberglass and Gel Coat Repair

-

Topside Boat Paint

- Above or Below the Waterline

- Aluminum Boat Paint

-

Awlgrip Marine Paint

- Awlgrip Polyester Urethane Topcoat

- Awlcraft 2000 Acrylic Urethane Topcoat

- Awlgrip Awlcraft® SE Topcoat

- Awlgrip HDT

- Awlcraft 3000

- Awlgrip Converters

- Awlgrip Reducers and Activators

- Awlgrip Primers/Sealers

- Awlgrip Fairing/Surfacing

- Awlgrip Awl-Prep Wipe Down Solvents

- Awlgrip Corrosion Inhibiting Surface Treatments

- Awlgrip Brightwork, Varnish, Interior Wood

- Awlgrip Auxiliary Products

- Awlgrip Maintenance Products

- Camouflage Boat Paint

- Blue Water Topside Paints

- Duralux Marine Paints

- Marine Enamels

- Interlux Topside Paint

- Pettit Easypoxy

- Adhesives and Sealants

- Teak Oil and Wood Restoration

- Boat Paint Supplies

- Resins

- Cleaners and Polish

- Manufacturers

- Propeller and Running Gear Coatings

Your shopping cart is empty!

Product Description

Crystal Clear Epoxy Table Top Resin, 1 Gallon Kit; Crystal clear system designed for table tops, bars, art work & other applications requiring a clear, plastic coating. Not recommended for projects that will be in direct sunlight. Includes Part A & B.

Size: 1 Gallon Kit

We highly recommend testing a sample piece before beginning your final project.

While using Epoxy Table Top Resin in castings, we recommend using thin pours of no more than 1/4”.

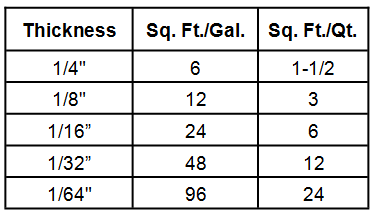

We recommend using the chart below to estimate coverage and thickness.

Directions for Use:

Step 1: The ideal working temperature is around 77°F. Best results can be obtained at temperatures between 70°F and 85°F, in a clean, dry, dust-free environment. Avoid working in high humidity. We recommend using this product on a leveled and flat work surface.

Step 2: Using the Laminate Coverage Chart, measure product in accordance with your intended use. Prepare 1 part Base Resin to 1 part Curing Agent by liquid volume or 100 parts Base Resin to 83 parts Curing Agent by weight. Pour the Curing Agent first and then the Base Resin into a clean, smooth-sided container large enough to hold all the liquid and allow room for mixing.

Step 3: The material must be mixed thoroughly for at least 3 minutes. Be sure to scrape the container sides, bottom, and corners as you mix. Be careful to not whip excessive air into the mixture. If mixing a gallon, use a power mixer set to hand speed. For smaller quantities, use stir sticks. Do not mix more than a gallon.

Step 4: Pour the mixed resin onto the surface and distribute evenly with a squeegee or gloved hand. Continue to pour remaining material to achieve the desired thickness, allowing the resin to flow evenly over the project's sides.

Step 5: See Additional Information for guidance to help eliminate bubbles that have risen to the surface of the resin.

Step 6: If you are going to make a second pour, the first pour should still be lightly sticky. Once the second pour is made, bubbles may once again need to be removed. Material will feel well-cured after 24 hours, but full cure and maximum hardness can require up to 7 days depending upon the temperature.